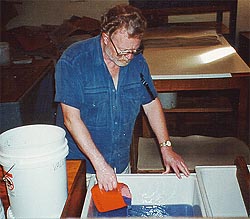

The papermaker adds the beaten pulp to a vat of water, creating a

slurry. The more pulp per unit of water, the thicker the formed sheets

become.

|

|

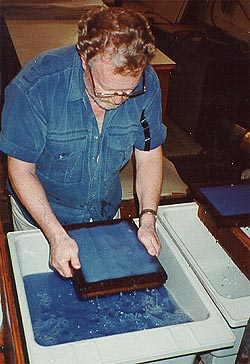

Using a mold (a wooden frame with a screen stretched over the surface)

and a deckle (the "fence" placed on top of the mold to keep

the slurry from running off the edges of the screen), the papermaker

forms sheets by scooping up a quantity of the slurry and shaking it to

cause

the fibers to interlink. |

|

Much of the water in the slurry on the newly formed sheet is allowed

to drain out of the sheet through the screen on the mold.

|

|

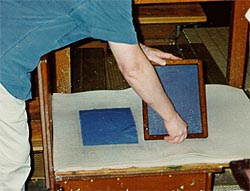

The deckle is removed to permit the removal of the sheet from the

mold. |

|

The newly formed sheet is then rolled off the mold onto a felt blanket

(couching), layering one felt on top of another. |

|

When there is a pile

of felts (a post), the whole "sandwich" is pressed under

considerable pressure until most of the water is removed. The

individual sheets are then removed from the felts and dried.

|

|